Trained, experienced and knowledgeable inspection technicians are the backbone for any successful inspection company. We can proudly claim that we possess over 100 years of experience and training.

Whether you are an experienced inspector, or are looking to get into a new, exciting line of work, Stealth Oilfield Inspections LTD has a position for you! Apply online today!

Stealth Oilfield Inspections LTD is constantly growing to serve our customers better. With offices in Red Deer, Grande Prairie and Drayton Valley, we serve customers all throughout Alberta and the Midwest - extending our reach to the Yukon and beyond.

The Stealth Advantage

Our team is made up of a group of individuals who, all together, have countless years of experience in the inspection industry.

Working quickly and safely, our team ensures that all work performed is of the highest quality, no matter the size of the job.

Using the best tools and following strict guidelines for safety and quality, our turnaround times are fast so you can get back to work!

At Stealth Oilfield Inspections, we were card to stay current with a new inspection technologies so we can provide faster, more accurate services to our customers.

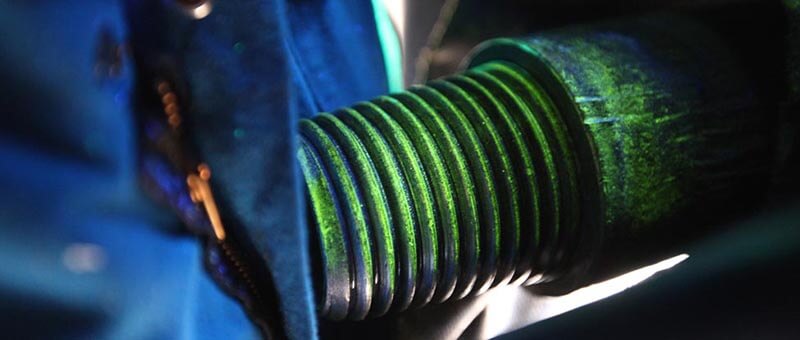

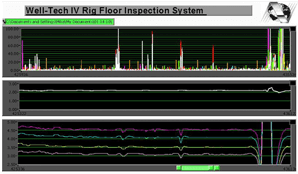

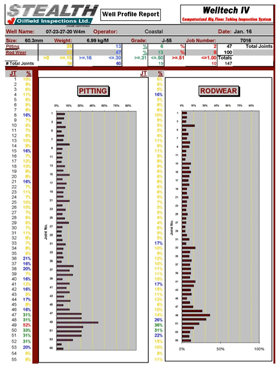

To aid in the minimizing of tubing failures and lower operating costs for our clients, Stealth continues to invest in the latest technology. The WellTech-IV™️ Rig Floor Inspection System is one of those investments, and is designed to inspect oilfield tubing on the rig floor while being pulled out of the well. With ease, the inspection head is lifted onto the rig floor by the rig hoist line and positioned over the slips. This allows the operator to see the slips operate with the inspection head in place. The WellTech-IV™️ provides fast on-site calibration and a reliable, quality inspection to put the world back in operation quickly. This guarantees the tubing owner's satisfaction of knowing the true condition of the tubing string.

Tubing Inspection capacity: 2 3/1" to 4 1/2" (with coupling).

Inspection speed range: Up to 250 ft/min.

Estimated time to calibrate: 10-20 minutes.

Transverse cracks, pTransverse cracks, padding, splits & holes (Split-chek), TRUE WALL™️ Solid state hall effects wall loss monitoring for large area corrosion and rod wear. The WellTech-IV™️ system runs all electronically with no radioactive materials present.

• TransverseFlaw, solid state hall effects technology (view each channel in different colors).

• Wall thickness monitering, solid state hall effects.

• New and Enhanced SPLIT-Chek longitudinal split and hole detection system.

• Digital constant current mag power supply.

• Computerized data acquisition, high speed computer system, color monitor & printer.

• View inspection data on laptop or desktop computer.

New compact size is 30% smaller and lighter than previous models:

• TRUE-WALL™️ solid state wall monitoring system.

• Exclusive "TFD" (TRUE FLAW DETECTION) System with solid state sensors.

• Guide/wipers built into head for pipe centralization & wiping of tube OD.

• Windows based software.

• Data acquisition spreadsheet program included for documentation by operator of pipe information i.e. reject data, joint no., etc.

• Each section of pipe is numbered and stored to desk, and can be reviewed as "Live Time."

• Well Profile Report indicates problem areas in string, which is an excellent management tool for use in tubing wear analysis and corrosion inhibitor programs.

Included in Stealth's quality management system is a review of all tubing inspection jobs. This monitors operator consistency and ensures that our standards are met on all jobs regardless of which branch or operator completed the inspection. These job reviews are discussed and reviewed with the employees so that we constantly monitor and improve our performance. Our operators are trained and experienced to analyze the readings to determine the most reliable judgment and to cull out tubing that would otherwise cause future failures without causing any undue costs and waste.

Stealth Oilfield Inspections LTD recognizes the importance of health and safety to our clients, as well as for our employees. Therefore we maintain a current COR as well as memberships to ISNetworld, Complyworks and the International Pipe Inspectors Association. We ensure that the services and products we use are designed, manufactured, and built to meet or exceed any relevant Canadian industry standards for safety. The company's health and safety policy states this commitment and outlines our approach to affective health and safety management. Our processes and procedures are designed to not only meet, but surpass, legal requirements and deliver a healthy, safe, and secure working environment for our employees and those in the surrounding area. Recognizing that the contributions of our employees make the backbone of our business, we are committed to helping them succeed. Not only offering them fair terms and conditions, we ensure they have all the skills and qualifications they need, and provide them with opportunities for training and development on a regular basis.

At Stealth Oilfield Inspections LTD, we are always on the lookout for the best talents in the field. Our team is made up of hard-working individuals dedicated to quality, professionalism, getting the job done safely, and on time. Don't wait, now is your chance to get on board! Check out the job postings below and applied to the one that best suit you!

CURRENT JOB OPENINGS

We are a privately owned company headquartered in Red Deer with operations in Drayton Valley and Grande Prairie. We currently have a NDT position open as a Field Operator at our Red Deer facility. Applicants must have experience in Mag Particle II, LP, and UT. Used Drill Pipe certificate experience and certificate would be preferred. As an Operator, you will be the senior tech on staff and are responsible for performing jobs as well as assisting with the junior staff. Your experience and knowledge will require you to be the lead operator on Drill Pipe inspection jobs. You will be required to ensure that all inspection equipment is maintained in the operator’s trucks and that calibrations are completed and recorded according to regulations. Your position will also require you to establish and maintain safety records and hold safety meetings with staff according to company and regulatory standards. Excellent salary and benefit package commensurate with level of experience and training. Assistance with relocating will be provided.

Please email resume to stealthm@telus.net. All personal information will be kept confidential.

Stealth Oilfield Inspections Ltd. utilizes modern technology to inspect tubulars at the well site and is currently accepting applications for the position of WELLHEAD TUBING INSPECTOR for our Red Deer office. Successful candidates will have extensive knowledge and experience with the tubular inspection process and Ultrasonic (U.T.) training would be an asset. Preference will be given to those that have NDT training courses and experience. Working knowledge of service rigs would also be an asset. Applicants must have a clean driving record and valid safety tickets.

Compensation and benefit package will reflect experience and training. Please email resumes to

mwalliser@stealthinspections.com

Duties

- Conduct inspections of Oilwell Tubulars at the well sites in compliance with safety standards and regulations

- Perform visual inspections, measurements, and tests to identify defects or malfunctions

- Document inspection results and prepare detailed reports

- Collaborate with other team members to address any issues or concerns identified during

inspections

- Follow established procedures and protocols to ensure consistent and accurate inspections

Skills

- Mechanical knowledge: Understanding of mechanical systems and components to identify

potential issues or defects

- Commercial driving: Possess a valid commercial driver’s license (CDL) to operate vehicles as

required for inspections

- Forklift operation: Skilled in operating forklifts to move materials and equipment as needed

- Attention to detail: Ability to carefully observe and identify even minor defects or issues during

inspections

- Strong communication skills: Able to effectively communicate inspection findings and

recommendations to team members and stakeholders

Successful candidates will have extensive knowledge and experience with the tubular inspection process and Ultrasonic (U.T.) training would be an asset. Preference will be given to those that have NDT training courses and experience. Working knowledge of service rigs would also be an asset.

Applicants must have a clean driving record and valid safety tickets. Compensation and benefit

package will reflect experience and training. Please email resumes to

mwalliser@stealthinspections.com

Note: Additional skills may be required based on specific job requirements.

Job Type: Full-time, Permanent

Salary: $6,000.00-$8,000.00 per month

Benefits Include:

• Dental care

• Disability insurance

• Extended health care

• Life insurance

• Vision care

Schedule:

• Monday to Friday

•On call

• Weekends as needed

Supplemental pay types:

• Bonus pay

• Commission pay

Work Location: On the road